Cu Mineral Crushing Process Picture

Understanding Mineral Liberation during Crushing Using

2020年2月13日Coarse comminution test-work and modeling are powerful tools in the design and optimization of mineral processing plants and

Mineral Processing Pictures, Images and Stock Photos

Browse 10,900+ mineral processing stock photos and images available, or search for mineral processing plant or gold mineral processing to find more great stock photos and pictures. mineral processing plant. gold

Crushing in Mineral Processing Eastman Rock Crusher

What Is The Crushing Process?Why Crushing?What Is The Crushing Stage?What Equipment Are Used in Crushing Process?

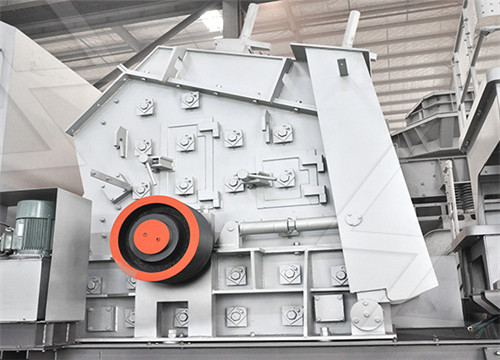

The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen into a 0-20 mm fraction and typically a 20-150 mm fraction. The 0-20 mm fraction contains soil etc. and is generally considered to be of poor quality. This...

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy)

Minerals Free Full-Text Optimizing the Crystalline

2020年9月17日This study investigated the effect of Na 2 CO 3 on the crystalline state of Cu slag and the recovery of Cu by flotation. The mechanism was investigated by

(PDF) Efficient Modeling and Control of Crushing

2019年12月10日This thesis focuses on developing models of crushers and equipment used in the mining industry. Specifically, the focus is on a branch of modeling called

cu mineral crushing process picture castello.pl

Sep 10, 2019 In this study, a novel process of mechanical crushing combined with a pyrolysis-enhanced flotation was developed to recover LiCoO 2 and graphite from spent

cu mineral crushing process picture

This process causes the Cu minerals to become selectively attached to air bubbles rising through a slurry of finely ground ore in water (Fig. 1.4).Selectivity of flotation is created by

cu mineral crushing process picture

Process steps include mining, concentration, roasting, smelting, converting, and finally fire and electrolytic refining. Process Description2-4 Mining produces ores with less than 1

Copper Production: How Is Copper Made? ThoughtCo

2019年9月26日The first step in this process is crushing and powdering ore in a ball or rod mill. Sulfide Copper Ores Virtually all sulfide-type copper ores, including chalcocite (Cu 2 S), chalcopyrite (CuFeS 2) and covellite (CuS), are treated by smelting.

Zaldívar Copper Mine Northern Chile Mining

2000年4月3日Barrick Gold Corp. (100%) Geology type Tertiary copper porphyry deposit with rhyolite-hosted primary sulphides overlain by secondary oxides and sulphides Mineral type Chalcocite, brochantite,

Copper Ore an overview ScienceDirect Topics

Flotation is preceded by crushing and grinding the mined Cu ore to small (∼100 μm diameter) particles. Its use has led to adoption of smelting processes that efficiently smelt finely ground solids. A video of mining and mineral processing may be seen in The Mining Process at Copper Mountain Mine. This mine produces 30,000 tonnes of ore and

Understanding Mineral Liberation during Crushing

2020年2月13日The liberation of ore minerals is a function of the rock texture and the difference in size and mechanical properties of the valuable minerals relative to gangue minerals and they may fraction in certain

Crushing in Mineral Processing Eastman Rock Crusher

2020年4月20日Crushing in Mineral Processing 2020-04-20 2020-04-20 / crusher plant The modern industrial use of aggregates began in the early 19th century, and the aggregate can be defined as particles of rock that,

Introduction to Mineral Processing Sepro Labs

There are three primary types of run-of-mine materials: 1. Run-of-mine consisting of useful materials. These could include granites, building sand, limestone, coal and clays. Note that materials in this category are not classified as minerals.

Mineral Processing Abstracts COPPER 2022

• Optimized operation at the Medium and Fine Crushing Sector with an efficient processing potential of 45% of the ore fed from the AG Sector • Increasing the throughput at the Ball Mill Area and improving the flotation slurry particle size distribution • Utmost state-of-the-art ore milling process management by an expert automated

What Is The Crushing Process MEKA

Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing".

Mineral Crushing Process Mining Pedia

2022年1月11日A Comprehensive Look at Talc Ore Processing Talc is a clay mineral that can be used in many industries, such as , , rubber, pharmaceuticals, cosmetics, etc. This article describes the ore properties, application areas, purification methods and mineral processing equipment of talc.

mineral crushing picture partyservice--stein.de

In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, e.g. barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum

Copper Production: How Is Copper Made? ThoughtCo

2019年9月26日The first step in this process is crushing and powdering ore in a ball or rod mill. Sulfide Copper Ores Virtually all sulfide-type copper ores, including chalcocite (Cu 2 S), chalcopyrite (CuFeS 2) and covellite (CuS), are treated by smelting.

Copper Ore an overview ScienceDirect Topics

Overview Mark E. Schlesinger, Gerardo R.F. Alvear Flores, in Extractive Metallurgy of Copper (Sixth Edition), 2022 1.3.1 Concentration by froth flotation Copper ores being mined in 2020 are far too dilute in Cu (0.3%–1.7%) to be smelted directly. Heating and melting their huge quantity of waste rock would require prohibitive amounts of fuel.

Crushing in Mineral Processing Eastman Rock Crusher

2020年4月20日Crushing in Mineral Processing 2020-04-20 2020-04-20 / crusher plant The modern industrial use of aggregates began in the early 19th century, and the aggregate can be defined as particles of rock that,

Mineral Processing Abstracts COPPER 2022

• Optimized operation at the Medium and Fine Crushing Sector with an efficient processing potential of 45% of the ore fed from the AG Sector • Increasing the throughput at the Ball Mill Area and improving the flotation slurry particle size distribution • Utmost state-of-the-art ore milling process management by an expert automated

Mineral Processing DECHEMA

Mineral Processing Mineral, renewable and secondary raw material processing current engineering challenges Policy document issued by the ProcessNet Subject Divisions: ??Comminution / Classification ??Interfacially Dominated Systems and Processes ??Mechanical Liquid Separation IMPRINT Authors

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The process "Comminution" involves size reduction and size-wise classification called as screening or separation. The objective of this report is to provide the details of size reduction methods

Chalcopyrite (Cu) Sphalerite (Zn) Separation by Flotation

2016年4月14日Copper 3.78%. Sulphur 42.38%. Zinc 12.45%. Gold 0.01 oz/ton. Iron 32.84%. Silver 1.50 oz/ton. Insoluble 8.50%. In order to meet smelter requirements it is desired to produce at least a 20% copper concentrate with not over 8% zinc. The copper is present principally as chalcopyrite in extremely close association with both the sphalerite

Mineral Crushing Process Mining Pedia

2022年1月11日A Comprehensive Look at Talc Ore Processing Talc is a clay mineral that can be used in many industries, such as , , rubber, pharmaceuticals, cosmetics, etc. This article describes the ore properties, application areas, purification methods and mineral processing equipment of talc.

cu mineral crushing process picture

Cu Mineral Crushing Process Picture Feed Back Wine Overview Encyclopedia Wine Overview Wine is an alcoholic beverage made by fermenting grape juice Although . Copper Chemical Element reaction water uses elements metal . The periodic table is a chart that shows how chemical elements are related to each other Today copper is obtained from

Pictures Mineral Crushing

Find the perfect Mineral Processing Plant stock photos and editorial news pictures from Getty Images Select from premium Mineral Processing Plant of the highest quality ; pictures of mineral crushing building,There are thousands of mineral discoveries with very few that reach the positive feasibility stage and Pyrrhotite and Crumbling

- дробилка свинцовая руда 100 тонн в час

- Шаровая и гоночная мельница на тепловой электростанции

- портативный камень crusehr четыре экрана с конусом

- Завод Дробилки Из Индии

- дробильное отделение обработка материалов

- мини мельница 637 0100 01 500

- подержанные поставщики дробилки железной руды

- Милл Микро Мокрый Мяч

- прейскурант строительных материалов в Андхра

- центробежно вибрационный грохот

- дробилка производитель машин в Германии

- проектирование конвейеров в свердловской области

- стоимость дроблениеа вибрационного для щебня

- продажа щебня гравия в москве обработка материалов

- Поиск ирригационных насосов

- добилка кварца фото обработка материалов

- Дробилка молотковая сурьма

- нужна ли шаровая мельница для глазури

- мельница мельница шаровая 1 5х3 Галерея

- Защита угольной шахты с использованием Zigbee

- Мобильная дробилка Производитель Индия

- флотационная камера при переработке шлака

- Производитель портативной дробилки kaolin Производитель в Нигерии

- дробилка щековая мелкого дробления дмд 160 100 боэзгро

- каменная дробилка ди томо majalengka