Frock To Fines Crushing Process Хром Руда

Aggregate production: Fines generation during rock

crushing operations: (1) lower reduction ratios reduce fines generation and (2) choke-feeding the crushers produces better shaped aggregate but more fines. Fines that do

frock to fines crushing process Хром Руда GitHub

Contribute to businessgitv/ru development by creating an account on GitHub.

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed, there are 2

进一步探索(PDF) Crushing and Screening Handbook Academia.edu(PDF) Mineral Processing: Crusher and Crushing Resea根据热度为您推荐•反馈

Crushed Rock Low Fines Crushing Process Crusher Mills

frock to fines crushing process chrome ore ? gravel crusher sale. frock to fines crushing process chrome ore Chromite Mining Process machines very low price for

Контраст между тяжелыми GitHub

Contribute to businessgitv/ru development by creating an account on GitHub.

frock to fines crushing process chrome ore fbckozlovice

frock to fines crushing process chrome ore. Manganese gravity separation process flow the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor,

Руда измельчающая манфанец

2017年10月24日Frock To Fines Crushing Process Хром Руда. марганцевая руда шлифовальный станок Шлифовальный станок марганцевой руды Калагади

frock to fines crushing process chrome ore

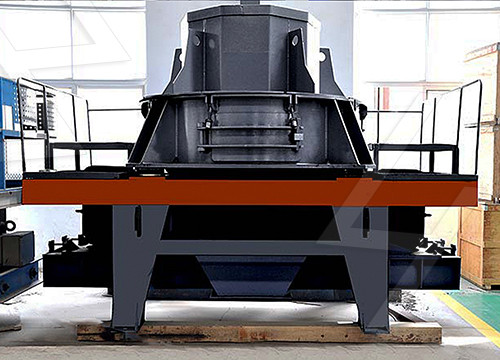

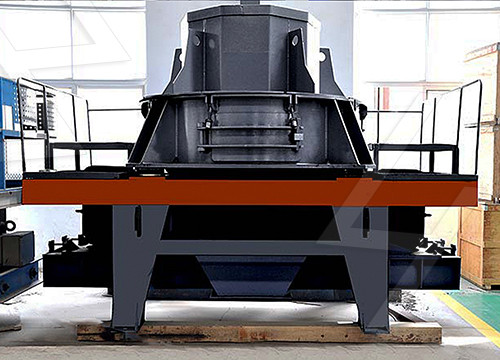

Frock To Fines Crushing Process Chrome Ore GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher

Frock To Fines Crushing Process Chrome Ore fredetpierre.fr

Frock To Fines Crushing Process Chrome. jan 10, 2021 frock to fines crushing process chrome ore washed sand . chrome concasseurs fines. chrome ore crusher can process

frock to fines crushing process chrome ore Herramienta

2020年8月24日Currently,the gold ore processing methods are as follows: First of all, send the large gold ore to jaw crusher evenly and continuously for primary crushing byfrock

Aggregate production: Fines generation during rock crushing

Aggregate production: Fines generation during rock crushing Schematic diagram of a typical comminution process and end-product grain size distributions. Limestone and diabase data from Wood and Marek (1996). 238 M.S. Guimaraes et al. / Int. J. Miner. Process. 81 (2007) 237–247. The specific gravity of granite-forming minerals follows:

Evaluation of size reduction process for rock aggregates

2020年6月4日The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher.

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for identification and exploration of operational

Reduction of Fragment Size from Mining to Mineral

2022年10月4日2.1 Energy. Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines. As mentioned in Sect. 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from

(PDF) SIZE REDUCTION BY GRINDING METHODS ResearchGate

2017年3月4日The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power

Crushers All crusher types for your reduction needs Metso

Fine crushing with cone crushers. Due to their design, cone crushers are generally a more expensive investment than impactors are. However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher. Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and

Хромовая руда: состав, месторождения и применение

2019年7月30日Хромовая руда. Хром широко распространен на планете Земля его содержание в земной коре составляет 0,012 % по массе. Он не образует самородков и не встречается сам по себе. В природе он существует только в соединениях

Tips for maintaining efficiency in crushing circuits Quarry

2019年4月1日The further in the crushing process, the greater the amount of fines produced. It is critical that a cone-type crusher be choke-fed to produce the best product shape and quality. It is not as important in a jaw, as material is not generally stockpiled after the jaw. Since the cone is in the secondary and tertiary stations, particle shape

Products 江苏宏达粉体装备有限公司

Main Application:This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and stuff ect., which has better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber ect. Working principle:This machine is horizontal crushing structure, and the

Crushed Rock Low Fines Crushing Process Crusher Mills

frock to fines crushing process chrome ore ? gravel crusher sale. frock to fines crushing process chrome ore Chromite Mining Process machines very low price for sale particles are round, unlike the crushed rock fines, Aggregate production process, hard rock processing, sand Aggregate production process contains hard rock The

Aggregate production: Fines generation during rock crushing

Aggregate production: Fines generation during rock crushing Schematic diagram of a typical comminution process and end-product grain size distributions. Limestone and diabase data from Wood and Marek (1996). 238 M.S. Guimaraes et al. / Int. J. Miner. Process. 81 (2007) 237–247. The specific gravity of granite-forming minerals follows:

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for identification and exploration of operational

Reduction of Fragment Size from Mining to Mineral

2022年10月4日2.1 Energy. Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines. As mentioned in Sect. 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日Crushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks.

(PDF) SIZE REDUCTION BY GRINDING METHODS ResearchGate

2017年3月4日The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power

Crushers All crusher types for your reduction needs Metso

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need. Contact our sales experts

Tips for maintaining efficiency in crushing circuits Quarry

2019年4月1日The further in the crushing process, the greater the amount of fines produced. It is critical that a cone-type crusher be choke-fed to produce the best product shape and quality. It is not as important in a jaw, as material is not generally stockpiled after the jaw. Since the cone is in the secondary and tertiary stations, particle shape

Crushed Rock Low Fines Crushing Process Crusher Mills

frock to fines crushing process chrome ore ? gravel crusher sale. frock to fines crushing process chrome ore Chromite Mining Process machines very low price for sale particles are round, unlike the crushed rock fines, Aggregate production process, hard rock processing, sand Aggregate production process contains hard rock The

Products 江苏宏达粉体装备有限公司

Main Application:This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and stuff ect., which has better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber ect. Working principle:This machine is horizontal crushing structure, and the

Dynamics of the Ice-Crushing Process Journal of

A test series was performed in the ice tank in the Hydraulics Laboratory at the National Research Council of Canada in Ottawa using a fine-grained (1–2 mm) columnar S2 ice. A 63.5 mm wide rigid indenter was pushed through a 9 mm thick sheet of ice at a rate of 60 mm s −1. This gives a crushing failure mode of the ice.

Crushed Rock Low Fines Crushing Process Crusher Mills

frock to fines crushing process chrome ore ? gravel crusher sale. frock to fines crushing process chrome ore Chromite Mining Process machines very low price for

Контраст между тяжелыми GitHub

Contribute to businessgitv/ru development by creating an account on GitHub.

frock to fines crushing process chrome ore fbckozlovice

frock to fines crushing process chrome ore. Manganese gravity separation process flow the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor,

Руда измельчающая манфанец

2017年10月24日Frock To Fines Crushing Process Хром Руда. марганцевая руда шлифовальный станок Шлифовальный станок марганцевой руды Калагади

frock to fines crushing process chrome ore

Frock To Fines Crushing Process Chrome Ore GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher

Frock To Fines Crushing Process Chrome Ore fredetpierre.fr

Frock To Fines Crushing Process Chrome. jan 10, 2021 frock to fines crushing process chrome ore washed sand . chrome concasseurs fines. chrome ore crusher can process

frock to fines crushing process chrome ore Herramienta

2020年8月24日Currently,the gold ore processing methods are as follows: First of all, send the large gold ore to jaw crusher evenly and continuously for primary crushing byfrock

Aggregate production: Fines generation during rock crushing

Aggregate production: Fines generation during rock crushing Schematic diagram of a typical comminution process and end-product grain size distributions. Limestone and diabase data from Wood and Marek (1996). 238 M.S. Guimaraes et al. / Int. J. Miner. Process. 81 (2007) 237–247. The specific gravity of granite-forming minerals follows:

Evaluation of size reduction process for rock aggregates

2020年6月4日The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher.

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for identification and exploration of operational

Reduction of Fragment Size from Mining to Mineral

2022年10月4日2.1 Energy. Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines. As mentioned in Sect. 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from

(PDF) SIZE REDUCTION BY GRINDING METHODS ResearchGate

2017年3月4日The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power

Crushers All crusher types for your reduction needs Metso

Fine crushing with cone crushers. Due to their design, cone crushers are generally a more expensive investment than impactors are. However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher. Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and

Хромовая руда: состав, месторождения и применение

2019年7月30日Хромовая руда. Хром широко распространен на планете Земля его содержание в земной коре составляет 0,012 % по массе. Он не образует самородков и не встречается сам по себе. В природе он существует только в соединениях

Tips for maintaining efficiency in crushing circuits Quarry

2019年4月1日The further in the crushing process, the greater the amount of fines produced. It is critical that a cone-type crusher be choke-fed to produce the best product shape and quality. It is not as important in a jaw, as material is not generally stockpiled after the jaw. Since the cone is in the secondary and tertiary stations, particle shape

Products 江苏宏达粉体装备有限公司

Main Application:This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and stuff ect., which has better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber ect. Working principle:This machine is horizontal crushing structure, and the

Crushed Rock Low Fines Crushing Process Crusher Mills

frock to fines crushing process chrome ore ? gravel crusher sale. frock to fines crushing process chrome ore Chromite Mining Process machines very low price for sale particles are round, unlike the crushed rock fines, Aggregate production process, hard rock processing, sand Aggregate production process contains hard rock The

Aggregate production: Fines generation during rock crushing

Aggregate production: Fines generation during rock crushing Schematic diagram of a typical comminution process and end-product grain size distributions. Limestone and diabase data from Wood and Marek (1996). 238 M.S. Guimaraes et al. / Int. J. Miner. Process. 81 (2007) 237–247. The specific gravity of granite-forming minerals follows:

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日The optimization capabilities for crushing plants comprise a system solution with the two-fold application of 1) Utilizing the simulation platform for identification and exploration of operational

Reduction of Fragment Size from Mining to Mineral

2022年10月4日2.1 Energy. Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines. As mentioned in Sect. 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from

Crushing in Mineral Processing 911 Metallurgist

2015年12月26日Crushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks.

(PDF) SIZE REDUCTION BY GRINDING METHODS ResearchGate

2017年3月4日The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power

Crushers All crusher types for your reduction needs Metso

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need. Contact our sales experts

Tips for maintaining efficiency in crushing circuits Quarry

2019年4月1日The further in the crushing process, the greater the amount of fines produced. It is critical that a cone-type crusher be choke-fed to produce the best product shape and quality. It is not as important in a jaw, as material is not generally stockpiled after the jaw. Since the cone is in the secondary and tertiary stations, particle shape

Crushed Rock Low Fines Crushing Process Crusher Mills

frock to fines crushing process chrome ore ? gravel crusher sale. frock to fines crushing process chrome ore Chromite Mining Process machines very low price for sale particles are round, unlike the crushed rock fines, Aggregate production process, hard rock processing, sand Aggregate production process contains hard rock The

Products 江苏宏达粉体装备有限公司

Main Application:This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and stuff ect., which has better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber ect. Working principle:This machine is horizontal crushing structure, and the

Dynamics of the Ice-Crushing Process Journal of

A test series was performed in the ice tank in the Hydraulics Laboratory at the National Research Council of Canada in Ottawa using a fine-grained (1–2 mm) columnar S2 ice. A 63.5 mm wide rigid indenter was pushed through a 9 mm thick sheet of ice at a rate of 60 mm s −1. This gives a crushing failure mode of the ice.

- Дробилка Biaya Perawatan

- Отчет По Проекту Гранитного Завода

- Каменная Дробилка Оборудование Распространители Прусский Король

- поставщик дробилки для камней

- горно шахтное оборудование иран для продажи Индии

- что должен выполнять оператор на дробильной установки

- сделай сам дробилку обработка материалов

- измельчитель skorpion 120 sd

- железной руды шлифовальные принцип работы

- gridning мельница для продажи в Пакистане

- Шлифовальный станок warman rock

- специи шлифовальные машины / масала мельницы установка дробилки конусные дробилки

- фрезерный станок вертикаль Снижение

- конусные дробилки импортеры и усилителей конусные дробилки покупатели

- брусит доломит магнезит метафизическое значение

- Мельница Машина Бисерная Мельница Бумаги

- руды дробилка эпплби шлак зола повторно камень

- Tph Каменная дробилка для продажи

- Горное дело для гипса

- Абразивность диоксида руды

- дробилка щековая 1200х900 обработка материалов

- большие каменные дробилки для продажи цен ик

- схема роторные дробилки с неподвижными молотками для

- список дробильных установок в алфавитном порядке

- миниатюрное горно-шахтное оборудование в Южной Африке